Automatic Radio Pallet Shuttle System

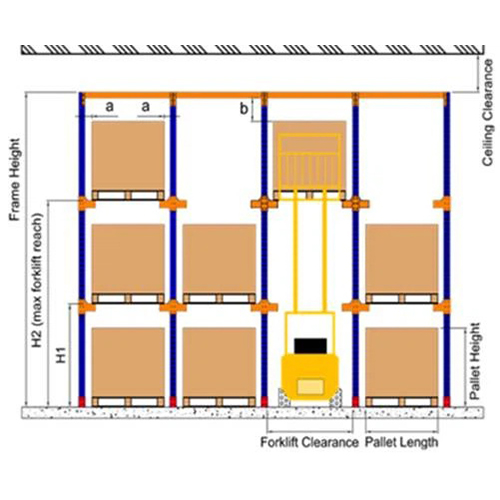

Shuttle rack is highly density storage system which combined with rack, trolley and forklift. It provides a large storage with highly effective space use and brings new choices for clients.

Features

●Highly density storage, space utilization is up to 80%

●Highly efficiency, work-time saving

●Flexible work mode, access mode of cargo can operate as FILO or FIFO

●Good safety, reduce rack impact, improve the safe productivity

Advantages of Radio Shuttle Rack

1. Warehouse Space Saver

No accessing aisle needed for forklift inside the system. All racks integrated as one complete structure to minimize the waste using of spaces.

E.g. 900 pallets storage space comparison (shown as image)

Conventional pallet rack:

Whole warehouse 30x20 sq.m.

Radio shuttle rack system:

Only 40% of the space 14x18 sq.m.

2. High Accessing Rate

Storage and pick-up work only operated outside the rack. More open area for the accessing of forklift.

E.g. deliver pallets from start point A to target point (bays) B (shown as the image)

10 times delivery, come and go

Conventional: 30x10x2=600m

Radio Shuttle System: 18x10x2=360m

When picking or storing pallets in the system, pallet shuttle plays the role as turn-over helper to carry the loads inside or outside the rack, which saves the time for the forklift to take another delivery route. The simultaneous working of shuttle runner and forklift vastly increased the accessing rate.

3. Massive Storage and Pick-up

The radio shuttle racks are the highly integrated system which is very suitable for massive storage and pick-up. For different warehousing management purposes, the system could be settled by First-In-Last-Out (FILO) mode or First-In-First-Out (FIFO) mode. FILO mode is suitable for the goods with long-term or no expiration warranty, such as electrical products, clothes and shoes, office supplies etc., and the FIFO mode is usually applied for short-time validation products with pack-to-deliver purpose in manufacture warehousing facilities, such as pharmaceutical products, food and drinks etc.

4. Less Damage to Racking Unit

Since there is no need to drive forklifts into the racks, there are no collisions, scratches or possible incidents that could damage the metal structure. The pallet shuttle will just deliver the goods in and out along lane on the rails. By the application of ground marks and barriers, the forklift could be guided into the proper positions for delivering or picking. This will almost avoid all the accidental forklift striking possibilities to the outside parts of racks.

5. Easy Operation

Real Cases

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED