High density drive in rack a kind of non - channel, continuous, whole - type rack, which is stored in a depth direction and one by one, which makes it possible to store high density.

Access to the cargos from the same side of the racks, the first deposit, the balance weight and forward type forklift can easily into the middle of the rack to access the cargos, without the need to occupy multiple aisles.

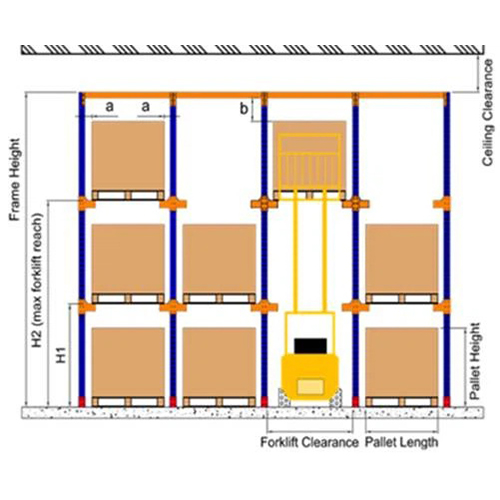

JT RACKING high density drive in rack is applicable for storing large quantities of cargos with few varieties. Drive in rack is the plug assembly type structure which column pieces assembled on the shelf area up to the total depth of wall can be designed within 7 pallet depth, middle area on both sides of the shelf total depth of import usually within 9 pallets, in order to improve the efficiency and reliability of the forklift access.

The investment cost is relatively low, which is suitable for the situation that the size is larger, the species is less, the quantity is large, and the mode of goods access can be scheduled. Drive in rack is widely used in various types of warehouses and logistics centers such as: food, tobacco, dairy, beverage and other industries, cold storage is also more common.

Drive in rack can provide the largest amount of storage space, widely used in large storage, small variety, frequent access to the industry, such as cold storage food, beverages, raw materials, dairy products and other industries.

Loading & Unloading

Safety is the most important in any workplace. When working with a drive-in pallet rack system, loading and unloading pallets safely and securely without causing damage to your product and pallet racks, also preventing injury to your employees is the biggest priority. Before using the drive-in racks, it is a good idea to make sure the forklift is compatible with the sizes of the racking system. Operators must enter the drive-in racks very slowly and carefully to avoid crushing on the pallet rack upright frames. Forklift operators need to be very careful when reversing out of the racking system when unloading as well, while taking all the same precautionary measures taken during the loading process.

Maintenance

Regular maintenance and upkeep is necessary to ensure the stability and safety of a drive-in pallet racking system. It is highly suggested that regular safety checks be performed to verify that the racking system hasn’t incurred any damage that may compromise the strength of the pallet rack or operator’s safety. Focus on checking for damaged frames, loose anchors, and damaged pallet rails.

We're one of the leading heavy duty drive in rack suppliers in China, equipped with a professional and productive factory at your service. If you are interested in heavy duty drive in rack, welcome to place orders.

RELATED

RELATED

RELATED

RELATED