Features

●4-Direction travel

●Smart control

●Integration of storage and distribution

Specification

Loading capactity:800-2000kgs

Speed:0.8m/s-1.2m/s

Shuttle height:180-247mm

Battery life :6-8H

Charge time:3-4H

Advantages

●Can make full use of to 90% of the total area

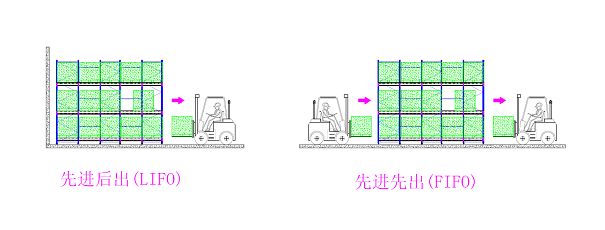

●Can store with both last in first out and first in first out system

●Reduce crashes between forklift and rack, Decreased incidents and maintenance costs

●Can reach 40meters deep

Technologies

1. Battery technology

The earliest shuttle car is a semi-automatic control mode, and its structure and system are simple. Battery technology is one of the key technologies that affect its application. The working time that can be met by each full charge becomes a bottleneck for shuttle car. While high performance batteries are expensive, the application of shuttle car is very limited. With the continuous improvement of the battery performance and the decline in the price after the production, the shuttle car has been widely used.

2. Electric quantity monitoring technology

In the early days, a big difficulty was the power monitoring of shuttle car. What would it do when the shuttle car suddenly had no electricity? And it really happens every day. If the power of shuttle car cannot be monitored effectively, the problem cannot be solved. This problem will cause the full automatic system and large system cannot be applied, which is one of the key reasons for the slow application of the shuttle system.

3. Communication and positioning technology

The early shuttle car caused inaccurate location due to communication problems, resulting in a large number of vacancies. However, frequent communication failures caused the equipment to be difficult to maintain, and to a large extent affect its use.

4. Technical difficulties of different types of shuttle bus system

4 direction radio shuttle provides a new solution for three-dimensional storage. It is a significant breakthrough in the storage technology of stereoscopic storage. The traditional AS/RS based storage design idea has been greatly impacted. However, the 4 direction radio route design of the shuttle system is very difficult, the scheduling system, the more difficult; in addition, due to the increase of the horizontal and vertical rail traffic control system, is also a very big problem, these problems are not resolved, will not be used on a large scale.

The invention of a multi-layer shuttle has solved the problem of the speed of access to people for a long time in the picking system of "goods to people". Prior to that, although the speed of miniload stacker has increased to an astonishing 350m/min, the access efficiency is limited to 100 times per hour for each car. The multi-layer shuttle car easily broke through this limit. The multi-layer shuttle car first solved the problem of fast charging. Now the fast charging device can charge in a few seconds and meet the requirements of the car for a few minutes, so that the car can achieve 24 hours' continuous work. This is a major technological breakthrough. In addition, the fork design of the multi-storey shuttle is also the key point. As the market division is more and finer, now there is a mature fork can be selected. The cost of the fork of the goods accounts for about 40% of the total cost of the car, and it can be seen from this point that it is important.

The difficulty of 4 direction radio shuttle lies mainly in the control and scheduling system, and the order management and route optimization algorithm are very complex and the control is more difficult. It is a great challenge to imagine a system with 500 shuttle car, how to schedule efficient jobs. The limited capacity of many systems is mainly due to the irrational scheduling of cars. In addition, the radio shuttle system requirements are very strict, the general shelf production process cannot meet the requirements. There are fewer manufacturers in China that can provide 4 direction radio shuttle orbits, which also set obstacles for the application.

The overall situation is: battery technology has made qualitative leap, fork also has mature products, but the control system and scheduling system cannot be purchased, making the large-scale logistics scene fully applied shuttle vehicle system is also facing great difficulty.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED