Choosing the appropriate storage shelf form for a warehouse involves a thorough analysis of the warehouse's actual situation and needs. The right choice can significantly impact efficiency, storage capacity, and accessibility. Here's a step-by-step guide to help you make an informed decision:

Assess Your Inventory:

Start by understanding the types of products or items you'll be storing. Consider their size, weight, dimensions, and any special requirements (e.g., temperature sensitivity, fragility).

Determine Storage Density:

Evaluate your warehouse's space and layout. Determine whether you need to maximize vertical space (high storage density) or if horizontal space is sufficient for your needs.

Consider Accessibility:

Analyze how often items need to be accessed. High-demand items should be easily reachable, while lower-demand items can be stored in less accessible areas.

Understand Handling Equipment:

Take into account the types of material handling equipment you'll be using, such as forklifts, pallet jacks, or conveyors. Your shelving choice should be compatible with your equipment.

Choose the Right Shelving Types:

Based on your assessment, select the appropriate shelving types. Common options include:

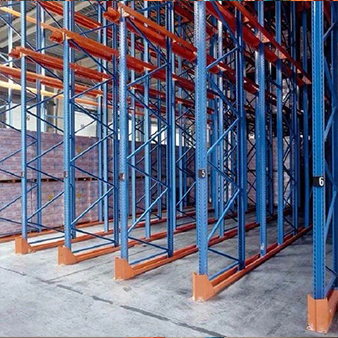

Pallet Racking: Ideal for storing palletized goods, available in selective, drive-in, or push-back configurations.

Cantilever Racking: Suitable for long, bulky items like pipes, lumber, or furniture.

Shelving Units: Versatile for storing smaller items, available in various designs like open, closed, wire, or mobile.

Mezzanines: Utilize vertical space with raised platforms for additional storage.

Bin Shelving: Organize small parts and inventory efficiently.

Flow Racks: Facilitate first-in-first-out (FIFO) inventory management for perishable or time-sensitive items.

Automated Storage and Retrieval Systems (AS/RS): For high-density and automated storage needs.

Consider Load Capacity:

Ensure that your chosen shelving can support the weight of your inventory. Check load capacity ratings provided by manufacturers.

Layout Design:

Create a layout that optimizes space utilization and ensures efficient pathways for material handling equipment and workers. Consider aisle width and the arrangement of shelving units.

Safety and Compliance:

Ensure that your shelving choice meets safety regulations and industry standards. Implement safety features such as rack guards, backstops, and anchor points.

Flexibility and Scalability:

Plan for future growth or changes in inventory. Choose shelving systems that can be easily expanded or reconfigured as needed.

Budget Constraints:

Consider your budget and balance it with the need for quality and durability. Remember that investing in high-quality shelving can pay off in the long run.

Consult Experts:

Consider seeking advice from warehouse design experts or consultants who can help you make the most appropriate shelving decisions based on your specific requirements.

Environmental Factors:

Evaluate any environmental factors, such as temperature and humidity, that may affect your shelving choice. Some items require specialized storage conditions.

Employee Ergonomics:

Ensure that the shelving arrangement is designed with the comfort and safety of warehouse staff in mind. This includes considering shelf height, aisle width, and accessibility.

By carefully analyzing these factors and considering the unique needs of your warehouse, you can select the most suitable storage shelf form that maximizes space utilization, improves efficiency, and meets your specific storage requirements.